Everyday since he was a pint-sized 12-year-old, Tulisi Bahadur Prajapati has collected clay and kneaded it with his feet. It's tiring, but nothing compared with what follows. Thimi's Prajapati potter community doesn't use the elegant little wheels most of us picture potters working with. They use old tyres filled with concrete that weigh more than 300 kg. Starting the wheels is so laborious, it is the only aspect of pot-making that Thimi's women don't participate in. The men turn these improvised wheels with a pole at a frenzied pace until the tyre is spinning fast enough for them to throw two or three pots in about five minutes. "It's incredible that the pots are so symmetrical. They're thrown so quickly and the tyre is so unstable and unpredictable," says Ani Kastan, an American potter who studied potting methods in Thimi. Larger pots, such as the deodas used to store chhang, are first built up out of clay coils and then beaten smooth with a paddle.

Everyday since he was a pint-sized 12-year-old, Tulisi Bahadur Prajapati has collected clay and kneaded it with his feet. It's tiring, but nothing compared with what follows. Thimi's Prajapati potter community doesn't use the elegant little wheels most of us picture potters working with. They use old tyres filled with concrete that weigh more than 300 kg. Starting the wheels is so laborious, it is the only aspect of pot-making that Thimi's women don't participate in. The men turn these improvised wheels with a pole at a frenzied pace until the tyre is spinning fast enough for them to throw two or three pots in about five minutes. "It's incredible that the pots are so symmetrical. They're thrown so quickly and the tyre is so unstable and unpredictable," says Ani Kastan, an American potter who studied potting methods in Thimi. Larger pots, such as the deodas used to store chhang, are first built up out of clay coils and then beaten smooth with a paddle.

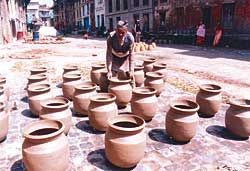

After the pots are completed they are dried in the sun, then fired in communal, makeshift kilns, that are built and destroyed every four days. Pots from each workshop are taken to the town square, where they are stacked up, covered with straw and ash, and then burned in a kind of smoke firing. Smoke and ash billow through the town's streets. Not surprisingly many Thimi residents have chronic lung problems. When the fire subsides and the ash is swept away, the pots are left to cool. It's common for over fifty percent of the pots to be destroyed during the firing process. Those that survive the firing are carried around to different villages in yokes and are sold door-to-door. "My father used to walk all the way from Thimi to Swoyambhu selling his pots," Santo Kumar Prajapati remembers. Today some potters have resorted to vehicles, but many still sell their wares by travelling on foot.

Tulisi Bahadur, now in his seventies, may have entered the family trade at the age of 12, but claims he learnt the art of pottery at a much younger age. Like many of Thimi's children, he began making pots as a toddler, playing with clay and imitating his father. Today, he and his wife Chinimaya maintain his father's pottery workshop on the first floor of their house, where they spend long hours throwing pots.

But of their four children, only their daughter has chosen to follow the family trade. Their three sons have moved to Kathmandu to work as tailors and in knitting factories. Even their daughter now works in her husband's workshop, leaving the couple with no one to bequeath their studio to. "I had hoped that all my children would become potters, but I didn't want to interfere with their wishes," says Tulisi Bahadur.  Nearly all of Thimi's inhabitants, who belong to the Newar Prajapati caste of potters, say their trade extends far back in their bloodlines. But of the estimated 8,000 Prajapatis who live in the area surrounding Thimi, only 2,000 claim that profession today. The others, like Bahadur Prajapati's sons, have sought more lucrative work in Kathmandu as bus drivers, waiters, or factory workers, leaving many family pottery workshops without an heir.

Nearly all of Thimi's inhabitants, who belong to the Newar Prajapati caste of potters, say their trade extends far back in their bloodlines. But of the estimated 8,000 Prajapatis who live in the area surrounding Thimi, only 2,000 claim that profession today. The others, like Bahadur Prajapati's sons, have sought more lucrative work in Kathmandu as bus drivers, waiters, or factory workers, leaving many family pottery workshops without an heir.

The high rate of defection from the potter trade is disconcerting, but by no means surprising. Potters all over Nepal work extremely hard for little economic compensation. Most of the potters in Thimi adhere to the arduous traditional methods in which every aspect of pottery production is completed manually-from mixing and drying the clay to powering the wheel. Of the roughly 1,000 workshops in Thimi, only four or five use modern potting technology such as electrically powered wheels and kerosene-fuelled kilns.

Since they don't have enough land to grow their own food, many potters walk to farms when rice and wheat are being harvested, trading storage pots for grain. They make just enough profit to survive on. "I go to Kathmandu to sell pots when I run out of money," explains Tulisi Bahadur. But even that is a challenge today. Few Nepalis are interested in earthenware pots when they can buy cheaper, longer-lasting mass-produced kitchenware made of steel or plastic.

With such impediments to their livelihood, it's no wonder that so many of Thimi's potters have forsaken their ancestral vocation. "Pottery is a very difficult profession now. It's hard work for little money," says Santo Kumar Prajapati, who owns Thimi Ceramics. Santo Kumar and his brother Laxmi Kumar realised early on that the obstacles facing the Valley's potters in producing and marketing their wares would only increase, and so in 1985 founded Thimi Ceramics, one of the town's first modern workshops. Moving with the times has allowed Santo Kumar and Laxmi Kumar to be innovative-and remarkably productive. In addition to electric wheels and pugging machines to mix clay, the brothers own one of few kerosene-fuelled kilns in the area, which can fire up to 3,000 pieces of glazed ceramics at a time. Unlike the unpredictable straw kilns used by most of Thimi's potters, the temperature in the brick kiln is adjustable, allowing the ceramics to first be fired at a low temperature and then refired at 1,000 degrees after they have been glazed. The double-firing technique melts the glaze and ensures that the ceramics are durable. "Nepalis don't want to pay for handmade pots that break easily. Potters need to find new methods," believes Santo Kumar.

Retaining traditional procedures isn't always a bad thing-as a tourist attraction at the Bhaktapur potters' square, it is a definite plus. But Thimi's potters have a lot more incentive to alter their archaic techniques-few tourists visit Thimi, and those who do aren't likely to lug home an enormous water storage vessel. But as Santo and Laxmi Kumar have discovered, traditional and modern potting methods can be blended to yield a product as aesthetically pleasing as it is practical. Combining classical designs with modern glaze technology, the Kumar brothers constantly create new models of tableware, garden ceramics, and decorative pieces that quickly get snapped up by hotels, restaurants, and foreigners. Their work is found at Hotel Yak & Yeti, Koto restaurant, and Hotel Kido, and colourfully glazed coffee mugs from Thimi Ceramics appear to be a staple in any expat's kitchen.

Bolstered by the success of their own workshop, Santo Kumar and Laxmi Kumar decided to bring other potters in the area up to speed. There have been attempts to modernise Thimi's potting techniques in the past, most notably by Jim Danish, an American potter who lived in Thimi for nine years to teach more expedient potting methods. Danish's most significant contribution to modern Nepali ceramics was glaze technology, which he taught Thimi's potters in 1980. More than just an aesthetic touch, glazing serves important practical functions, making ceramics more durable and hygienic. The red terracotta clay that Thimi potters use is extremely porous, making it unsafe as kitchenware. Food and liquids easily seep into the clay and remain there as fodder for bacteria. Glazing provides a protective shield, and strangely enough, was unknown in the Valley before Danish introduced it.

In 1984, Danish founded the Ceramics Production Project, a German-sponsored organisation that provided training workshops and sold raw materials relatively cheaply. Ten years later, however, the project was bought up by the private sector and discontinued the sale of materials to local potters. That's when Santo Kumar and Laxmi Kumar started their own collective, the Nepal Ceramics Co-operative Society, which now supplies materials for 14 pottery workshops and 37 potters from Thimi and Bhaktapur. "You can't get all ingredients for the glaze in Kathmandu. For flint, feldspar, potash, quartz, and chromium oxide we have to go to India. We go once a year and get enough materials for everyone in the collective," says Santo Kumar. The ingredients necessary for glazing would be prohibitively expensive, as well as difficult for most potters to obtain, but through the collective they can procure these materials at a reasonable cost.  In addition to providing the chemicals and minerals necessary for glaze, the collective offers workshops for potters who want to learn new techniques. Three months ago, a Swiss expert came to teach a new glaze method at the collective. Though Nepal's ceramics are still fathoms behind the rest of the world in most respects, the glazed pottery produced here is technically superior to ceramics in Europe, China, India, and America-it is lead-free and non-toxic.

In addition to providing the chemicals and minerals necessary for glaze, the collective offers workshops for potters who want to learn new techniques. Three months ago, a Swiss expert came to teach a new glaze method at the collective. Though Nepal's ceramics are still fathoms behind the rest of the world in most respects, the glazed pottery produced here is technically superior to ceramics in Europe, China, India, and America-it is lead-free and non-toxic.

Even today, Nepal's ceramic work has been eclipsed by products from India and China, both of which can mass-produce more durable stoneware. Kathmandu Valley potters have until now been limited to the brittle red terracotta clay locally available and found under the topsoil of rice fields. But members of the collective are developing ways to introduce stoneware clay to pottery workshops here. The research is expensive and requires imported Indian equipment. Even the kerosene kiln operated by Santo Kumar and Laxmi Kumar is unsuitable for stoneware firing, which requires a minimum temperature of 1,280 degrees. At such a high temperature, the brick kiln would melt, resulting in a huge gas explosion. At the collective, however, a small high fire kiln has been constructed and is being used to experiment with stoneware clay and new glazes.

If the research at the collective is successful, there is hope that domestically produced pottery will one day supplant foreign merchandise in the ceramic market. But Nepal's potters have a long way to go before they'll be equipped to compete with Indian imports. "To rival India, we need to be able to produce longer lasting stoneware ceramics. We'll have to replace all our equipment, and that's expensive," says Santo Kumar. Such an undertaking will require substantial capital investment and time, but for the moment, the technical advances being made in workshops in Thimi and Bhaktapur signal that a movement to reinvigorate Nepal's ceramic work is underway. If nothing else, the Nepal Ceramics Cooperative society is working to ensure that Kathmandu Valley's pottery tradition won't decline further.